Cold drawing is a process that reduces the diameter of seamless pipe & tube, coil tube and capillary tube. This is done by applying a mandrel to the metal, which then reduces its outer diameter and wall thickness.

The best way to detect chatter is to use a system that analyzes high-frequency data and translates it into a speed-reduction recommendation for the machine. These systems have been proven to prevent chatter from leaving lasting damage on your product.

It’s Fast and Efficient

Using an automatic cold drawing machine means you can reduce the diameter of steel wire as much as you need. This allows you to make a variety of products, including galvanized and bright wire, barbed wire, fences wire, bailing wire, and concrete reinforcement steel mesh.

The system of the automatic wire drawing machine is designed to be efficient. This includes a high-speed shaft drive, an internal water cooling system for the die block and an active motor control. This allows the machine to reach high-speed production with the lowest possible power consumption.

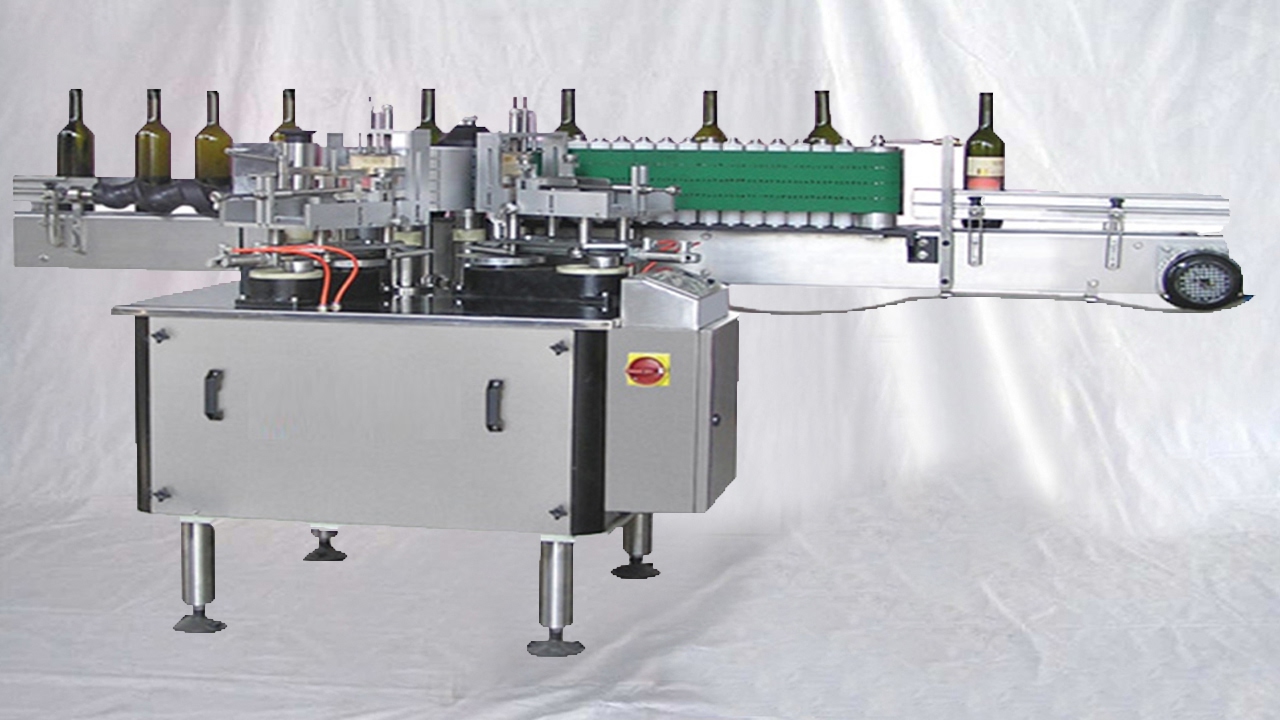

Horenco has a full line of turnkey equipment that makes it easy for companies to produce metal tubes and bars with precision and strict tolerances. Its cold drawing and swaging machines are both automatic and semi-automatic. These machines are ideal for a wide range of industrial applications. They are also cost-effective and feature a low error tolerance. Learn more about these machines by visiting the company website.

It’s Easy to Operate

Horenco’s new line of swaging, auto cold drawing and straightening machines is designed to help manufacturers with a variety of products. These turnkey machinery systems are easy to operate and can save businesses a lot of money in the long run.

These systems are also extremely efficient and require little maintenance. They’re made from high-quality steel and have many features that make them easy to use. For example, the swaging machine can reshape the ends of tubes and pipes to make them easier to connect with other parts. It’s a great time-saver for manufacturers and can improve the quality of their final products.

The calamine stripping machine removes calamine, which is a coating of iron that’s left on the rod during its hot production process. This makes it easier for the drawing machine to draw the metal. This machine is a must-have for anyone who draws brass, mild steel and alloy wires. It can even reduce the diameter of these materials by up to 50%.

It’s Easy to Maintain

HOREN’s HS model series automates the cold drawing process to eliminate swaging, saving time and money for manufacturers. It’s designed to draw both round and hexagonal carbon steel bars, as well as linear guide rails and other symmetrical alloys.

It’s important to note that the main spooler motor must be strong enough to both drive a full-weight spool at maximum speed and accelerate it from stationary start. To do this, the spooler motor must also account for the time it takes to build up acceleration to the maximum speed.

Some modern machines use forced air-cooling on their capstans, which can help prevent overheating of the wire during draw. However, this can be expensive to install and operate, since it adds to the cost of electricity. Moreover, the extra air movement disperses drawing soap around the machine and creates environmental problems. Thus, manufacturers should carefully consider whether a forced air-cooling system is necessary for their application before choosing this option.

It’s Affordable

Horenco knows that their new line of machinery is going to change the way manufacturers work, and they want to make it as easy as possible for customers to get their hands on it. That’s why they’ve made it clear on their website how to purchase a machine, and why customers can also contact them with any questions that may arise.

The auto cold drawing machine is ideal for use with metals such as brass, copper, and aluminum. It is designed to reshape these materials, making them easier to work with and improving their overall quality. It can also be used to draw out a range of other products, including metal rods and wires.

HOREN’s HS model is a chain-type machine that uses a hydraulic push pointer to draw metal tubes and bars with consideration for precision and strict tolerance. From loading to discharging, the process is fully automated. The drawn materials are carried to designated collection racks next to the machine.

Leave a Reply