How to Install

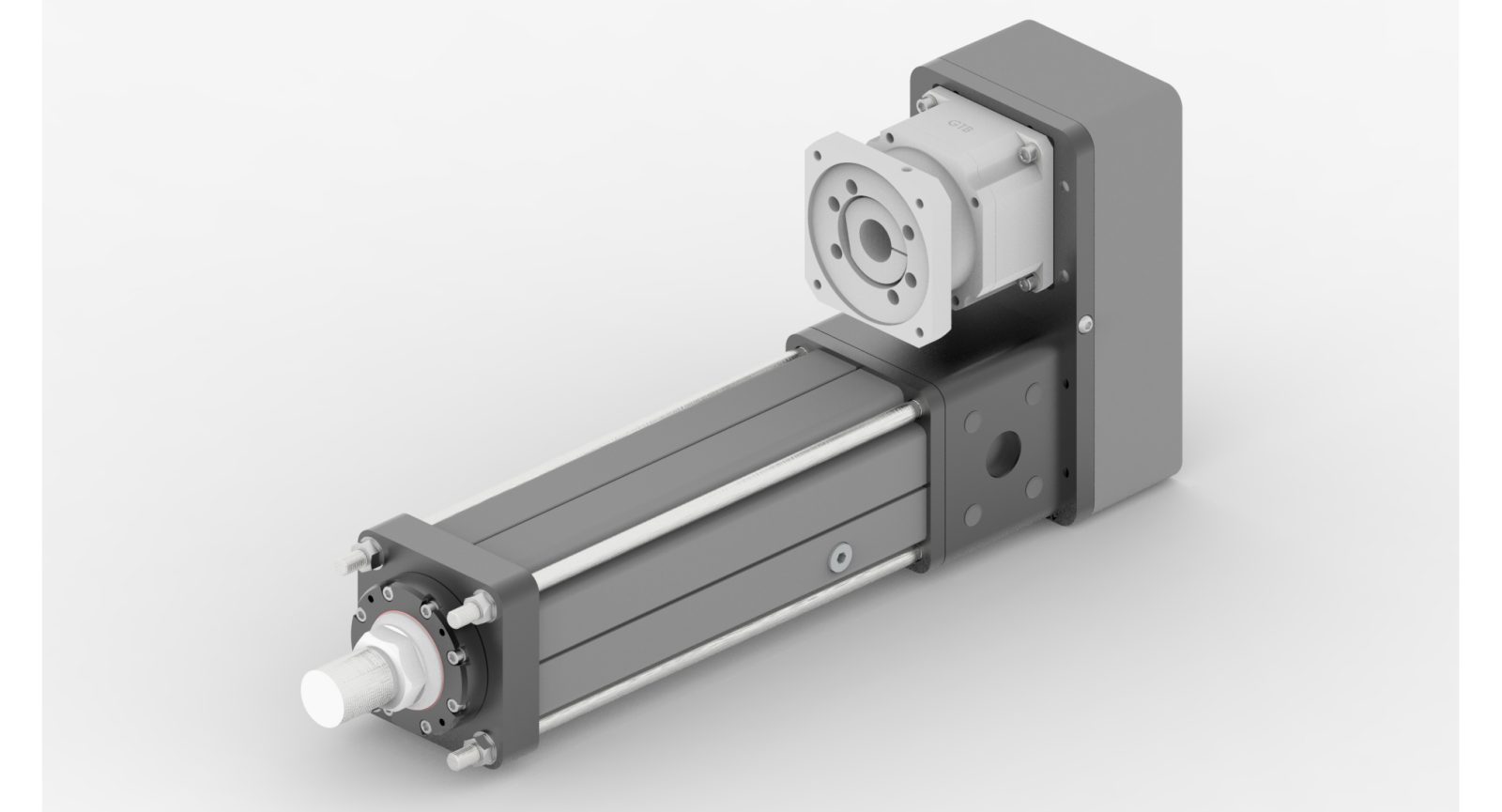

Unlike linear actuators, which use electrical energy to exert force in a straight line, electric rotary actuators move an object in a circular motion. They are ideal for applications in potentially explosive environments where hazardous gas and dust may be present.

With ATEX and other global certifications, they provide reliable valve automation in oil/gas, chemical/pharma and other facilities handling combustible materials. They feature flameproof enclosures with conduit seals that prevent sparks during operation, and they withstand the high pressures of blast events.

The WE and XE explosion-proof electric actuators are designed to operate quarter turn ball valves, butterfly valves, plug valves and dampers. The hard anodizing and polyester powder coating on the aluminum alloy housing equip them with strong corrosion resistance. They are also weatherproof and feature visual and electrical valve position indication and manual override. Their 4-pin connector connects easily to a standard power supply with wires of different colors—red on the actuator is connected to brown and blue on the connector is connected to black.

Maintenance

Often referred to as the James Bond of actuators, explosion proof electric actuators are designed to withstand an internal explosion without the risk of external explosion. These electric actuators feature fail-safe mechanisms that reset to a safe position during power outages or system failures.

Explosion Proof Electric Actuators are designed to actuate quarter turn ball valves, butterfly valves, plug valves, and dampers. They can be used in hazardous environments such as Zone 1 (explosive gas atmospheres) or Zone 2 (combustible dust atmospheres).

It is recommended that you follow the installation, maintenance and operational instructions listed in the operations manual for each model to ensure correct operation and avoid any potential hazards. Always disconnect the power supply before undertaking any electrical/mechanical works on the actuator to prevent any injury or equipment damage. Also, ensure the IP rated cable glands are sealed properly to prevent any external moisture from entering the actuator. Also, it is highly recommended that you use a surge protector to protect your actuator from power spikes.

Troubleshooting

If you have a question about how an Explosion Proof Electric Actuator works or are having trouble with one, it is important to understand how this type of device is built and how it can be repaired. You can get help from professionals to solve any problems you might have with an electric actuator.

One of the most important things to look for in an actuator is its load capacity. The higher the capacity, the more it can lift. Also, the distance that can be moved – called stroke length – is another metric you should take into consideration when shopping for an actuator.

You want an explosion-proof electric actuator that can handle a large amount of force. This means that it can move the desired object quickly, which is why it’s important to find an actuator with high torque rating. This metric can be determined by looking at the specifications of each model. Also, you should make sure that the actuator has a fail-safe feature to prevent any issues in case of power failure or malfunction.

Safety

Incorporating fail-safe features, these actuators shift to a safe position in the event of loss of power or an external malfunction. They’re the maestros of industrial automation, conducting a complex orchestra with finesse.

There are several performance metrics to consider when choosing an electric actuator. The most important are speed and torque. Speed measures how quickly the actuator can turn on or off a valve, while torque is the force required to move it.

Easily automate quarter turn ball valves, butterfly valves, and dampers with these explosion proof electric actuators. They meet UL HazLoc, ATEX, and IECEx standards for use in potentially explosive environments and are suitable for systems with operating pressures up to 300 bar. These actuators feature visual and electrical valve position indication, manual override, and weatherproof housings. They are also available in a variety of electrical output models, reflecting the amount of torque they can deliver.Explosion Proof Electric Actuator – YouTube

Leave a Reply