Screws are a common fixture in shops, but not all are created equal. Understanding how to sort and select the right screws can save you time, money and frustration.

To get the most out of your woodworking screws, you need to understand their gauge and length. A general rule of thumb is to select a screw that enters at least half the thickness of the material it will be attached to.

Length

The length of a screw is important because it determines how far into the material the threads will go. Too short, and the screw won’t be able to grip the material; too long, and it may extend past the item it’s being used on and cause damage.

When determining which length screw is right for a job, take into account the screw’s diameter and head shape. Flat heads require a longer screw than oval or round heads, for example.

Manufacturers usually categorize fasteners by their major diameter and nominal length. When a screw is labeled with two numbers and a suffix, such as #9-15 x 1″, the first number denotes the major diameter, while the second number represents the thread count. The third number, the shaft length in inches, is known as the nominal length and does not include the head. This measurement is often shortened to a single number when listing the screw size on packaging, such as 10-35 x 2″. This is called nominal sizing.

Diameter

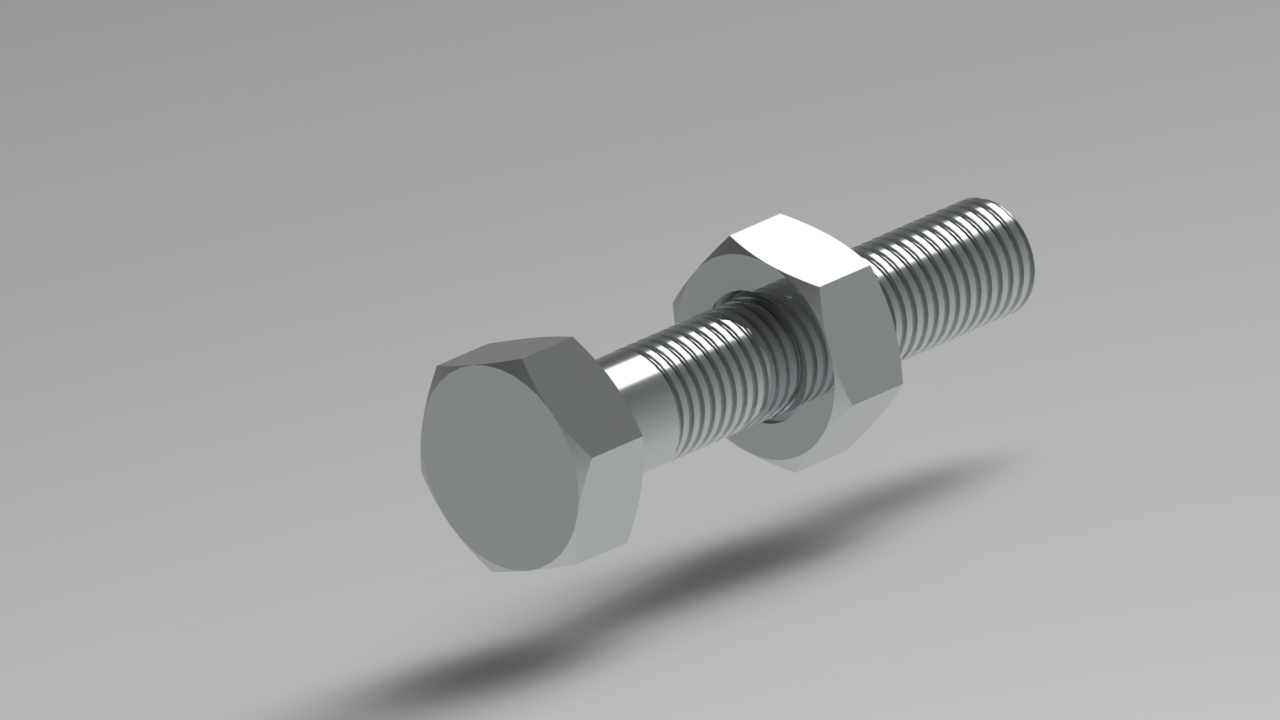

The diameter of a screw refers to the width of its threaded part and is measured in inches or millimeters, depending on the system used. Diameter is the first number in the thread size, and metric screws have their major diameter indicated by a number preceded by “M.”

In terms of pitch, which is the distance between each crest on adjacent threads, it can be helpful to think of a screw as a wave. The higher the pitch, the coarser the threads, and the lower the pitch, the finer the threads.

In a study of pedicle screws, Yorur et al found that equivalent stress decreased with increasing screw diameter and length, particularly at flexion. This suggests that it is important to consider the screw size when selecting a fastener for use in a particular application. It is also essential to consider the screw shank. This is the portion of the screw that extends past the head and into the wood, so it needs to be able to resist the load of the bone screw.

Threads Per Inch

Screw threads can be standardized in different ways depending on the industry and the country. The two main systems are the Unified Thread Standard (UTS) and the ISO metric system.

Both have their benefits, but there are some key differences. Mostly the difference is in how spacing and density of the threads are measured. Threads per inch (TPI) and pitch are inverse measurements of each other but accomplish the same goal of measuring how close together the threads are on a fastener.

TPI is used with American fasteners, while metric fasteners use thread pitch. TPI is a measurement of how many threads there are in an inch of a fastener, and it usually comes after the screw gauge (see below). The example shown below is a Senco Duraspin #8 washer-head screw with a major diameter of 0.084″. Check out our handy screw sizes chart for more information about screw gauges and their decimal equivalents. For more technical articles about helically coiled screw threads, register to KATOpedia today!

Gauge

The gauge of a screw is the larger of two extreme diameters delimiting the height of the thread profile. It can be measured by comparing the major diameter to the minor diameter. The major diameter can be a bit difficult to measure directly (as it is obstructed by the threads themselves) but may be tested with go/no-go gauges or, if you’re working in the metric system, by observing the number on the sleeve and multiplying that by 0.25.

The other measurement that often comes before the gauge is the thread pitch, or lead (/’lid/), which is the distance between the crest of one thread and the trough of the next thread. Engineering Toolbox has a handy chart that shows how these measurements are used for each screw size and their decimal equivalents. For example, the number on the sleeve of a #8 Senco Duraspin washer-head screw is equal to 0.064″. You can also use this chart to calculate the TPI (threads per inch) of your screws.3/4 to mm

Leave a Reply